|

|

06-16-2013, 06:55 PM

06-16-2013, 06:55 PM

|

#21

|

|

Mod free 5er

Join Date: Mar 2008

Location: Concord, NC

Posts: 24,702

|

Quote:

Originally Posted by Iggy

Just a guess but one of the reversing valves at the pump didn't switch and I bet you had pressure on both sides of the piston at the same time to do that much damage.

Call Lippert immediately and tell them what you have and what is the closest dealer you can take it to.

|

If pressures were the same on both sides of the piston, there would no motion to bend anything. Newton's 3rd law of motion. The slide had to be in a bind somewhere to bend the shaft.

__________________

|

|

|

06-16-2013, 07:22 PM

06-16-2013, 07:22 PM

|

#22

|

|

Senior Member

Join Date: Apr 2008

Location: Edmonton.Alberta,Canada

Posts: 163

|

Quote:

Originally Posted by OldCoot

If pressures were the same on both sides of the piston, there would no motion to bend anything. Newton's 3rd law of motion. The slide had to be in a bind somewhere to bend the shaft.

|

Old Coot

Cylinder rod may move just because of the area difference, usually will extend, "piston side" , now if this was a double rod style cylinder area is equal so no movement but no reason for that bent rod though : thumbsup:

|

|

|

06-16-2013, 07:43 PM

06-16-2013, 07:43 PM

|

#23

|

|

Mod free 5er

Join Date: Mar 2008

Location: Concord, NC

Posts: 24,702

|

Quote:

Originally Posted by win

Old Coot

Cylinder rod may move just because of the area difference, usually will extend, "piston side" , now if this was a double rod style cylinder area is equal so no movement but no reason for that bent rod though : thumbsup:

|

Made 2 assumptions, both cylinders the same size and also if it was a double rod cyl. No reason to believe the retract cyl would be different size than the extend as the loads should be the same in both directions, maybe a little less on the retract due to awning, etc. but not enough to require two different cyl sizes.

__________________

|

|

|

06-16-2013, 08:02 PM

06-16-2013, 08:02 PM

|

#24

|

|

Senior Member

Join Date: Dec 2011

Posts: 3,570

|

I guess what I was trying to say is the system maintains about 1300 on both sides of the jacks and slide pistons at all times. To move valve allows pump pressure to admit to the desired direction of the movement, meanwhile its exhaust hose is allowed to slowly drain to the sump. Must maintain pressure both sides or the actuator "will take off". The bend occurred most likely because the piston was allowed to stroke too far outboard. The bend is most likely at the end of the stroke because its so close to the piston. The set up is to allow the piston to bottom out just as the gaskets are compressed. This looks like over travel of at least 1".

Not sure Newtons 3rd applies here, that action and reaction like a jet engine.

This is most referred to in Hydraulics.

Bernoulli's principle

From Wikipedia, the free encyclopedia

Jump to: navigation, search

This article is about Bernoulli's principle and Bernoulli's equation in fluid dynamics. For Bernoulli's theorem in probability, see law of large numbers. For an unrelated topic in ordinary differential equations, see Bernoulli differential equation.

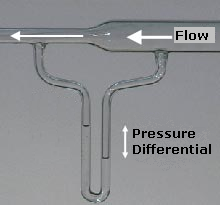

A flow of air into a venturi meter. The kinetic energy increases at the expense of the fluid pressure, as shown by the difference in height of the two columns of water.

Continuum mechanics

In fluid dynamics, Bernoulli's principle states that for an inviscid flow, an increase in the speed of the fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid's potential energy. [1][2] Bernoulli's principle is named after the Swiss scientist Daniel Bernoulli who published his principle in his book Hydrodynamica in 1738. [3]

Bernoulli's principle can be applied to various types of fluid flow, resulting in what is loosely denoted as Bernoulli's equation. In fact, there are different forms of the Bernoulli equation for different types of flow. The simple form of Bernoulli's principle is valid for incompressible flows (e.g. most liquid flows) and also for compressible flows (e.g. gases) moving at low Mach numbers (usually less than 0.3). More advanced forms may in some cases be applied to compressible flows at higher Mach numbers (see the derivations of the Bernoulli equation).

Bernoulli's principle can be derived from the principle of conservation of energy. This states that, in a steady flow, the sum of all forms of mechanical energy in a fluid along a streamline is the same at all points on that streamline. This requires that the sum of kinetic energy and potential energy remain constant. Thus an increase in the speed of the fluid occurs proportionately with an increase in both its dynamic pressure and kinetic energy, and a decrease in its static pressure and potential energy. If the fluid is flowing out of a reservoir, the sum of all forms of energy is the same on all streamlines because in a reservoir the energy per unit volume (the sum of pressure and gravitational potential ρ g h) is the same everywhere. [4]

Bernoulli's principle can also be derived directly from Newton's 2nd law. If a small volume of fluid is flowing horizontally from a region of high pressure to a region of low pressure, then there is more pressure behind than in front. This gives a net force on the volume, accelerating it along the streamline. [5][6][7]

Fluid particles are subject only to pressure and their own weight. If a fluid is flowing horizontally and along a section of a streamline, where the speed increases it can only be because the fluid on that section has moved from a region of higher pressure to a region of lower pressure; and if its speed decreases, it can only be because it has moved from a region of lower pressure to a region of higher pressure. Consequently, within a fluid flowing horizontally, the highest speed occurs where the pressure is lowest, and the lowest speed occurs where the pressure is highest.

|

|

|

06-17-2013, 06:21 PM

06-17-2013, 06:21 PM

|

#25

|

|

Senior Member

Join Date: Apr 2008

Location: Edmonton.Alberta,Canada

Posts: 163

|

If you want to get into Hydraulic laws Pascal is the guy, Fluid power engineering use Pascals law for force

Bernoulli laws are used for velocity, pressure drops in piping, and sizing hydraulic components, and pipe for proper Delta P

The word “hydraulics” generally refers to power produced by moving liquids.

Modern hydraulics is defined as the use of confined liquid to transmit power,

multiply force, or produce motion.

Though hydraulic power in the form of water wheels and other simple devices

has been in use for centuries, the principles of hydraulics weren’t formulated

into scientific law until the 17th century. It was then that French philosopher

Blaise Pascal discovered that liquids cannot be compressed. He discovered a

law which states: Pressure applied on a confined fluid is transmitted in all

directions with equal force on equal areas.

To better understand Pascal’s Law, lets use a bottle full of liquid as an

example. Let’s say the bottle has a 1 square inch opening. If we were to

apply 10 pounds of force on a cork at the opening, 10 pounds of force would

be applied equally to all sides of the bottle. This is expressed as 10 psi or

10 pounds of force per square inch. 10 psi represents the fluid pressure

of the system.

|

|

|

06-17-2013, 06:59 PM

06-17-2013, 06:59 PM

|

#26

|

|

Senior Member

Join Date: Dec 2011

Posts: 3,570

|

Quote:

Originally Posted by win

If you want to get into Hydraulic laws Pascal is the guy, Fluid power engineering use Pascals law for force

Bernoulli laws are used for velocity, pressure drops in piping, and sizing hydraulic components, and pipe for proper Delta P

The word “hydraulics” generally refers to power produced by moving liquids.

Modern hydraulics is defined as the use of confined liquid to transmit power,

multiply force, or produce motion.

Though hydraulic power in the form of water wheels and other simple devices

has been in use for centuries, the principles of hydraulics weren’t formulated

into scientific law until the 17th century. It was then that French philosopher

Blaise Pascal discovered that liquids cannot be compressed. He discovered a

law which states: Pressure applied on a confined fluid is transmitted in all

directions with equal force on equal areas.

To better understand Pascal’s Law, lets use a bottle full of liquid as an

example. Let’s say the bottle has a 1 square inch opening. If we were to

apply 10 pounds of force on a cork at the opening, 10 pounds of force would

be applied equally to all sides of the bottle. This is expressed as 10 psi or

10 pounds of force per square inch. 10 psi represents the fluid pressure

of the system.

|

Ok so more than these two gents made hydraulics available today. So lets change it to mechanics, what caused the piston rod to bend as it did? The bend appears to have occurred at near the end of the stroke. I checked mine today and the rods are all still slack in the thrust end brackets due the the lost motion in the piston rod lock nuts. I noted one that has only 1/16" clearance in the out position. If his setting was goofed by the repairer, than its easy to imagine the slide was full out while the piston still had stroke. That's what I believe happened to him. BTW the system is secret but best I can tell pressures are around 1200-1400 psi. The rod is 3/4-7/8 diameter plus it head and seal, that is a lot of force.......

|

|

|

06-17-2013, 07:25 PM

06-17-2013, 07:25 PM

|

#27

|

|

Senior Member

Join Date: Apr 2008

Location: Edmonton.Alberta,Canada

Posts: 163

|

Your absolutely correct, the rod needs to be bottomed out in the extend position as stated before and then do your adjustments, but to have that type of bend im sure as you stated before it had to be out by at least 1"

Yes that is a lot of force, something has to break.

Sorry to the OP just trying top help

|

|

|

06-17-2013, 07:57 PM

06-17-2013, 07:57 PM

|

#28

|

|

Senior Member

Join Date: Apr 2008

Location: Edmonton.Alberta,Canada

Posts: 163

|

Just did a quick calculation

If the cylinder bore was 2" @ 1400 psi and rod .750", force would be 4,400 lbs

At 1200 psi force is 3770 lbs

|

|

|

06-18-2013, 08:38 AM

06-18-2013, 08:38 AM

|

#29

|

|

Senior Member

Join Date: Nov 2010

Location: Wherever we are parked!

Posts: 424

|

To help the OP, I think we need to get back to what caused the problem to begin with. Something in the SLIDE is in a bind or the piston rod/slide attachment is out of adjustment. If the OP was to say to the repair person "Bernoulli's principle" he would be laughed at.

__________________

Lostdog

2011 Georgetown 378TS in FireMist

2013 Jeep Wrangler Toad

Kirby the Old Dog, passed but still in our hearts

Max E. Dog, the new pup

Eureka the Old Cat, still hangin' on

|

|

|

06-18-2013, 09:52 AM

06-18-2013, 09:52 AM

|

#30

|

|

2012 Georgetown 378

Join Date: Jan 2012

Location: Darlington, SC

Posts: 121

|

Quote:

Originally Posted by VinceU

Ok so more than these two gents made hydraulics available today. So lets change it to mechanics, what caused the piston rod to bend as it did? The bend appears to have occurred at near the end of the stroke. I checked mine today and the rods are all still slack in the thrust end brackets due the the lost motion in the piston rod lock nuts. I noted one that has only 1/16" clearance in the out position. If his setting was goofed by the repairer, than its easy to imagine the slide was full out while the piston still had stroke. That's what I believe happened to him. BTW the system is secret but best I can tell pressures are around 1200-1400 psi. The rod is 3/4-7/8 diameter plus it head and seal, that is a lot of force.......

|

Vince, do you and Win know for SURE that the rod needs to be fully extended and then adjusted to that point? I spent a lot of time on Lipperts web site and found this..

Extending Slide out room

1...

2...

3...

4... Press and hold the IN/OUT switch in the OUT position until the room is fully extended and stops moving.

5... Release the switch, which will lock the room into position

NOTE: If the slideout switch is held after the room is fully extended, the control will sense that the room has stopped and will shut off the motor after a few seconds"

Seems to me that this may be a design issue. the rod end of the cylinder is not supported in any way, if it was it would not have had the 6 or so feet from contact point to contact point to be able to bend, it would have been more like 30" or so. I just want to get it fixed so we can use it and deal with any issues later. Already have one out, unfortunately the other one is bent as well. not nearly as bad but if I am going to do it right, I am going to do both. the problem with doing the other one is that one end is connected to the slide under the entry stairs..what a bi... just to get to it!

__________________

Ray, Cynthia, Duncan and Bailey

2012 Georgetown 378

2006 HD Ultra

1992 Fat Boy

|

|

|

06-18-2013, 10:32 AM

06-18-2013, 10:32 AM

|

#31

|

|

Senior Member

Join Date: Dec 2011

Posts: 3,570

|

Quote:

Originally Posted by Lostdog

To help the OP, I think we need to get back to what caused the problem to begin with. Something in the SLIDE is in a bind or the piston rod/slide attachment is out of adjustment. If the OP was to say to the repair person "Bernoulli's principle" he would be laughed at.

|

Read posts 15, 24, and 26. They all refer to a misalignment of the guide system. Rather refer BP to a mechanic than AFU!

|

|

|

06-18-2013, 10:49 AM

06-18-2013, 10:49 AM

|

#32

|

|

Senior Member

Join Date: Dec 2011

Posts: 3,570

|

Quote:

Originally Posted by raycyn778

Vince, do you and Win know for SURE that the rod needs to be fully extended and then adjusted to that point? I spent a lot of time on Lipperts web site and found this..

Extending Slide out room

1...

2...

3...

4... Press and hold the IN/OUT switch in the OUT position until the room is fully extended and stops moving.

5... Release the switch, which will lock the room into position

NOTE: If the slideout switch is held after the room is fully extended, the control will sense that the room has stopped and will shut off the motor after a few seconds"

Seems to me that this may be a design issue. the rod end of the cylinder is not supported in any way, if it was it would not have had the 6 or so feet from contact point to contact point to be able to bend, it would have been more like 30" or so. I just want to get it fixed so we can use it and deal with any issues later. Already have one out, unfortunately the other one is bent as well. not nearly as bad but if I am going to do it right, I am going to do both. the problem with doing the other one is that one end is connected to the slide under the entry stairs..what a bi... just to get to it!

|

Partly bent is like partly pregnant, no good, you made the right call. To put them back I would leave the nuts very slack. Slowly operate the system to the extend position and follow the measurements in the book for proper slack motion. I check the rest of mine today where accessible and in all cases the rod is slightly loose in the bracket with lost motion down stream, and the slide out against the gaskets.

Your item five doesn't exist in any Lippert system I've seen spoken to. Like Win and I both stated they simply two block and you must release the button.

My book showed a reversible drill to extend and retract at the pump. Another myth, they have reversible valve I oil side for years now.

The piston rod adjustments were in the back of the book. If not there you can find on LCI1.com. I think in the future to watch the slide and listen to the pump at the end of travel. If not sure let go of the button, you can always reapply. If the piston bottoms out, it cannot bend anything, just don't overdo it.

Oh yes ask the shop if they can straighten the slight bent shaft with a lathe and heat. It may save a buck, maybe not.

|

|

|

06-18-2013, 08:11 PM

06-18-2013, 08:11 PM

|

#33

|

|

Senior Member

Join Date: Apr 2008

Location: Edmonton.Alberta,Canada

Posts: 163

|

Quote:

Originally Posted by raycyn778

Vince, do you and Win know for SURE that the rod needs to be fully extended and then adjusted to that point? I spent a lot of time on Lipperts web site and found this..

Extending Slide out room

1...

2...

3...

4... Press and hold the IN/OUT switch in the OUT position until the room is fully extended and stops moving.

5... Release the switch, which will lock the room into position

NOTE: If the slideout switch is held after the room is fully extended, the control will sense that the room has stopped and will shut off the motor after a few seconds"

Seems to me that this may be a design issue. the rod end of the cylinder is not supported in any way, if it was it would not have had the 6 or so feet from contact point to contact point to be able to bend, it would have been more like 30" or so. I just want to get it fixed so we can use it and deal with any issues later. Already have one out, unfortunately the other one is bent as well. not nearly as bad but if I am going to do it right, I am going to do both. the problem with doing the other one is that one end is connected to the slide under the entry stairs..what a bi... just to get to it!

|

Im not 100% sure but it just seems logical to fully extend and then do your adjustments

I attached 2 PDFs for you maybe that will help

|

|

|

06-19-2013, 01:02 PM

06-19-2013, 01:02 PM

|

#34

|

|

Senior Member

Join Date: Jan 2010

Posts: 191

|

Just a couple of notes regarding previous comments:

FIRST

Previous Comment:

My book showed a reversible drill to extend and retract at the pump. Another myth, they have reversible valve I oil side for years now.

Maybe I'm reading the manual wrong, but the following seems to support

the use of a drill to simulate the normal motor drive.

Source = Lippert Hydraulic Slideout Manual

The Lippert Hydro-Sync Slideout System can be run with auxiliary power devices

like electric drills, ratchet wrenches or cordless screwdrivers. In the event of

electrical or system failure, this manual method of extending and retracting the

slideout room can be used. A standard handheld drill is all that is required. A

standard 38" room will take approximately 45 seconds to retract.

Run drill forward or clockwise to extend slideout room and in reverse or

counterclockwise to retract slideout room.

seconds to retract.

SECOND

It appears that raycyn778 comments quoted below are correct, if the pressure switch

operates as indicated in LIP 0100.

Previous Comment:

NOTE: If the slideout switch is held after the room is fully extended, the control will sense that the room has stopped and will shut off the motor after a few seconds"

SOURCE = LIP 0100

AUTOMATIC PUMP SHUT OFF GOES THROUGH THE PRESSURE SWITCH. IF THE PUMP DOES NOT BUILD ENOUGH PRESSURE TO OPEN THE PRESSURE SWITCH, THE SYSTEM DOES NOT SHUT OFF.

Just some food for thought

Gary

|

|

|

06-19-2013, 06:38 PM

06-19-2013, 06:38 PM

|

#35

|

|

2012 Georgetown 378

Join Date: Jan 2012

Location: Darlington, SC

Posts: 121

|

Quote:

Originally Posted by win

Im not 100% sure but it just seems logical to fully extend and then do your adjustments

I attached 2 PDFs for you maybe that will help

|

Win, great attachments, thanks. I have removed both main room slides and and looking into having them straightened. The bends were not that bad but we will see what the opinion of the hydraulic repair shop in the next town over is. What I am trying to find out now is the procedure for putting them back into the unit. Will they equalize in length on their own? Do I fully extend them before putting the nuts on and adjust from there? Been trying to reach April Conner for a name and number of someone who knows. No answer for three days. Tried reaching Steve, left a message, no return call. Spoke with someone named Nicole at Lippert, don't think she likes her job very much..really rude. "We only send parts to Forest river, we don't know what they do with them!!!!" Could not tell me how they are adjusted and she works on the customer info line..

__________________

Ray, Cynthia, Duncan and Bailey

2012 Georgetown 378

2006 HD Ultra

1992 Fat Boy

|

|

|

06-19-2013, 08:36 PM

06-19-2013, 08:36 PM

|

#36

|

|

Senior Member

Join Date: Apr 2008

Location: Edmonton.Alberta,Canada

Posts: 163

|

Quote:

Originally Posted by raycyn778

Win, great attachments, thanks. I have removed both main room slides and and looking into having them straightened. The bends were not that bad but we will see what the opinion of the hydraulic repair shop in the next town over is. What I am trying to find out now is the procedure for putting them back into the unit. Will they equalize in length on their own? Do I fully extend them before putting the nuts on and adjust from there? Been trying to reach April Conner for a name and number of someone who knows. No answer for three days. Tried reaching Steve, left a message, no return call. Spoke with someone named Nicole at Lippert, don't think she likes her job very much..really rude. "We only send parts to Forest river, we don't know what they do with them!!!!" Could not tell me how they are adjusted and she works on the customer info line..

|

raycyn

I want to caution you on straightening the rods, once they bend even just a little , it weakens the rod material and will break or bend again with little force, the molecules in the rod have stretched and will never be the same strength, you should replace with new, have your hydraulic service shop make new ones, do NOT put heat on the rods that will compromise the chrome and will rust and that will wipe out the rod seals

|

|

|

06-19-2013, 08:41 PM

06-19-2013, 08:41 PM

|

#37

|

|

Mod free 5er

Join Date: Mar 2008

Location: Concord, NC

Posts: 24,702

|

Quote:

Originally Posted by win

raycyn

I want to caution you on straightening the rods, once they bend even just a little , it weakens the rod material and will break or bend again with little force, the molecules in the rod have stretched and will never be the same strength, you should replace with new, have your hydraulic service shop make new ones, do NOT put heat on the rods that will compromise the chrome and will rust and that will wipe out the rod seals

|

If he is taking them to a hyd. cyl. shop, they will not use heat, they will pad the rod so as to not scar it and mechanically bend it back straight. Shouldn't hurt the shaft in anyway. Mechanical properties will not be altered if heat is not used. OP's shafts are not bent that bad.

__________________

|

|

|

06-19-2013, 09:06 PM

06-19-2013, 09:06 PM

|

#38

|

|

Senior Member

Join Date: Apr 2008

Location: Edmonton.Alberta,Canada

Posts: 163

|

Quote:

Originally Posted by OldCoot

If he is taking them to a hyd. cyl. shop, they will not use heat, they will pad the rod so as to not scar it and mechanically bend it back straight. Shouldn't hurt the shaft in anyway. Mechanical properties will not be altered if heat is not used. OP's shafts are not bent that bad.

|

Ok then no problem im only giving info on HYRAULICS from 35 years experience

Take a piece of steel rod something that you can bend with your arms back and forth, what happens it creates heat and breaks, sure its just a rv slide and its not heavy equipment so not a big deal right! but why take a chance it not going to cost a lot more to do it RIGHT

Im done

|

|

|

06-19-2013, 09:17 PM

06-19-2013, 09:17 PM

|

#39

|

|

Mod free 5er

Join Date: Mar 2008

Location: Concord, NC

Posts: 24,702

|

Quote:

Originally Posted by win

Ok then no problem im only giving info on HYRAULICS from 35 years experience

Take a piece of steel rod something that you can bend with your arms back and forth, what happens it creates heat and breaks, sure its just a rv slide and its not heavy equipment so not a big deal right! but why take a chance it not going to cost a lot more to do it RIGHT

Im done

|

Not arguing with you, but they straighten hyd. shafts in the mfg process also. OP's is bowed, not bent and they will not be bending it back and forth.

It's OP's $ and decision and no right or wrong.

I'm outa here.

__________________

|

|

|

06-19-2013, 09:29 PM

06-19-2013, 09:29 PM

|

#40

|

|

Senior Member

Join Date: Dec 2011

Posts: 3,570

|

Quote:

Originally Posted by win

Ok then no problem im only giving info on HYRAULICS from 35 years experience

Take a piece of steel rod something that you can bend with your arms back and forth, what happens it creates heat and breaks, sure its just a rv slide and its not heavy equipment so not a big deal right! but why take a chance it not going to cost a lot more to do it RIGHT

Im done

|

Just for laughs google "Straighten shafting" there's over 100 sites, more than 1/2 use heat as a energy to cause straightening w/o shaft damage. This is LCI were talking not NASA. These rods will not be cheap to fabricate.

Ray I suggest you try to reach Gary in the support division, he seemed quite knowledgeable about these systems.

Just to close, in my line of work it was routine have 10' long sections of 1 11/16" shafting straightened after a pump failure. For shops that know how its routine to bring large shaft back to .001" of original.

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Discussions

» Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|