|

|

09-14-2017, 05:15 PM

09-14-2017, 05:15 PM

|

#21

|

|

Junior Member

Join Date: Dec 2014

Posts: 10

|

I have a Ultra Lite 2604WS and submitted a request 2 days ago to FR for recommended jacking points. Still waiting on response. Will post response if and when.

|

|

|

09-14-2017, 09:05 PM

09-14-2017, 09:05 PM

|

#22

|

|

Member

Join Date: Dec 2014

Posts: 59

|

Interesting discussion! I suppose my greatest concern will come someday sooner than later....what is going to happen when I decide to take my Flagstaff to a tire dealer to replace the China bombs with 4 new tires? The tire shop or techs are surely not going to raise one wheel at a time. I am guessing they are going to just shove a floor under "wherever they want" and jack the hell out of my trailer. Anybody had any experience with this venture or scenario?

__________________

Harlan & Pattie in MD

2017 Flagstaff 832 IKBS

2017 F-250 Crew 4X4 6.2L

|

|

|

09-14-2017, 09:34 PM

09-14-2017, 09:34 PM

|

#23

|

|

Senior Member

Join Date: Sep 2015

Location: SF Bay Area

Posts: 849

|

Quote:

Originally Posted by MHBroker

Interesting discussion! I suppose my greatest concern will come someday sooner than later....what is going to happen when I decide to take my Flagstaff to a tire dealer to replace the China bombs with 4 new tires? The tire shop or techs are surely not going to raise one wheel at a time. I am guessing they are going to just shove a floor under "wherever they want" and jack the hell out of my trailer. Anybody had any experience with this venture or scenario?

|

Yup, if it wasn't for this forum and reading about where to jack it up, my axle probably would have been toast on the first tire set change. I had a blowout, took it in to the tire shop close by where the blowout happened and had all 4 tires replaced. I walked back to where the tech was changing the tires to ask if he wanted me to remove the TPMS sensors and he was just about to jack the trailer up by the front axle. I told him that from what I understood that is not a good jacking point, he went and asked another guy and the other guy told him to jack it on the frame.

The second set I stuck around and the Tech did it right without me saying anything. This was a huge Good Year dealer that mainly deals with big trucks and trailers.

__________________

2016 Windjammer 3006WK - Sold July 2018

2002 Lance Lite 835EC TC - Sold July 2015

2010 Dodge Ram 2500, 4x4, Diesel, Front Hitch, Air Lift 5000 Rear Air Bags, Sold Mar 2019.

MISSION COMPLETED!

|

|

|

09-14-2017, 09:38 PM

09-14-2017, 09:38 PM

|

#24

|

|

DanLE

Join Date: Aug 2017

Location: Rockford, IL

Posts: 26

|

If I were in your shoes I'd be printing out some of the photos from these earlier posts to show the guys at the tire shop how you want your trailer properly jacked up to avoid any damage to the torsion axles. I had a similar experience this early Spring when I traded up to our current V-Lite 30wlrs from a smaller Puma 25rs. I kept the near new 10ply 15" tires and wheels off our 28' Puma and had them moved to the V-Lite. The dealership where we traded up didn't carry V-Lites or Windjammers and I wasn't about to have them screw up our newer trailer over a tire swap by improper jacking so I referred them to both Forest River and Dexter websites that clarified exactly how to go about jacking a trailer with torsion axles. I can only assume they complied with my request in that regard since I wasn't on site when the swap was done. We had a great Summer of camping (40 days between early June and later August, with more to follow yet this Fall after my wife has some time to recover from some upcoming surgery) The trailer has followed us nicely for a few thousand miles and has shown no signs of unusual or abnormal tread wear.

|

|

|

09-14-2017, 09:53 PM

09-14-2017, 09:53 PM

|

#25

|

|

Senior Member

Join Date: Nov 2012

Location: Michigan

Posts: 597

|

Quote:

Originally Posted by Restcure

When I put Goodyear Endurance tires on our trailer this spring I did not jack by the axles tube but I did place the axle stands right where the OP's photo shows the jack - as close to the hub as possible. Between the skirting covering most of our frame and those 3/16" or 1/4" steel flanges I decided it was the best place. And the stands did not fold, bend, spindle, mutilate or otherwise compromise the axles.

Bottle jack placement

Stand placement

|

Those pictures are exactly like I do my trailer, except that my jack is red:-)! I just do one side at a time and take my time. I only put the jack stands under for safety in case the jack slips down (it didn't). It isn't too hard to do at all and by doing it yourself with a break bar (to get them off), a torque wrench and the proper socket, you can get the settings exactly right. This last time, I took two tires off and went to the Goodyear dealer and had them put the new tires on the rims and balance them. Went back, put the new tires on and went to the other side of the trailer and repeated the process. Now I know for sure nobody put an impact wrench on my lugs and that the nuts are at the correct tightness. For the little extra time it takes, it is absolutely worth it. We have a Windjammer with the torsion bars and it works great.

|

|

|

09-14-2017, 10:19 PM

09-14-2017, 10:19 PM

|

#26

|

|

DanLE

Join Date: Aug 2017

Location: Rockford, IL

Posts: 26

|

I had a BAD experience a few years ago when an inexperienced kid at a Sam's Club over-torqued the lug nuts on our Chevy Van TV. 500 miles down the road we heard a loud BANG and here comes the right rear tire, wheel, and hub rolling past us on the shoulder. Stopped safely and a AAA flatbed was able to haul our van and tow our trailer to a AAA service center that completed the several hundred dollar repairs for us while we "camped" in their parking lot hooked up to their electric power. ;-) Sam's Club should have rightly reimbursed us, but they showed us where the "fine print" stated we were to have had the wheel re-torqued after 50-100 miles. As you can guess no one at Sam's Club gave us any indication that failure to complete that service would void any service warranties. Now I observe the torquing process every time I get tires installed to physically witness that the torque wrench actually rotates the individual lug nuts some BEFORE it 'clicks-in' the correct torque ft-lbs.

|

|

|

09-15-2017, 04:40 AM

09-15-2017, 04:40 AM

|

#27

|

|

Senior Member

Join Date: May 2016

Posts: 967

|

Quote:

Originally Posted by ProfChuck

Those pictures are exactly like I do my trailer, except that my jack is red:-)! I just do one side at a time and take my time. I only put the jack stands under for safety in case the jack slips down (it didn't). It isn't too hard to do at all and by doing it yourself with a break bar (to get them off), a torque wrench and the proper socket, you can get the settings exactly right. This last time, I took two tires off and went to the Goodyear dealer and had them put the new tires on the rims and balance them. Went back, put the new tires on and went to the other side of the trailer and repeated the process. Now I know for sure nobody put an impact wrench on my lugs and that the nuts are at the correct tightness. For the little extra time it takes, it is absolutely worth it. We have a Windjammer with the torsion bars and it works great.

|

Quote:

Originally Posted by DanLE

I had a BAD experience a few years ago when an inexperienced kid at a Sam's Club over-torqued the lug nuts on our Chevy Van TV. 500 miles down the road we heard a loud BANG and here comes the right rear tire, wheel, and hub rolling past us on the shoulder. Stopped safely and a AAA flatbed was able to haul our van and tow our trailer to a AAA service center that completed the several hundred dollar repairs for us while we "camped" in their parking lot hooked up to their electric power. ;-) Sam's Club should have rightly reimbursed us, but they showed us where the "fine print" stated we were to have had the wheel re-torqued after 50-100 miles. As you can guess no one at Sam's Club gave us any indication that failure to complete that service would void any service warranties. Now I observe the torquing process every time I get tires installed to physically witness that the torque wrench actually rotates the individual lug nuts some BEFORE it 'clicks-in' the correct torque ft-lbs.

|

I did all four at once to save myself from two trips to the tire shop. I was impressed that all four wheels and the 4 new unmounted tires fit in Dad's Hyundai Sonata (my truck was hitched to the trailer throughout the change).

The less an air wrench is applied to your lugs nuts, the better... that's my opinion! I always ask as shop to hand-tighten with a torque wrench and I hope they do, but you never know what goes on unless you stay and watch. But time is money and you can be pretty sure they're going from zero to 100 ft-lbs, so to speak, without gradual torquing - see below.

When I was in my teens my Dad taught me how to torque wheel lug nuts properly. He learned himself at a young age from a heavy equipment mechanic, who explained that fasteners torqued in this way can be relied upon not to loosen... especially useful when those fasteners are difficult to access. The method is a combination of pattern and gradual application of torque. I've used it for since the first time I put a wheel on a car and it has served me well.

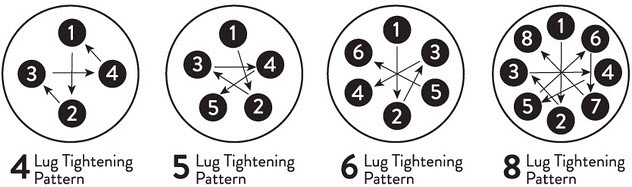

The torque pattern is pretty simple:

In combination with the pattern is the gradual application of torque. One third of the spec for all lugs, then two thirds, then full torque.

So when I'm installing a trailer tire, here's my procedure:

- Place the tire on the hub - I usually do this from a sitting position, balancing the tire on my feet.

- Finger-tighten the lug nuts while shifting the tire with my feet - this helps to ensure that the cones of the lug nuts centre the wheels on the lugs. I repeat this, moving from one nut to another, until all are finger-tight. At this point I'll snug them up a bit more with breaker bar and socket, but not much.

- Lower the trailer until all the weight is on the tires.

- Set the torque wrench to one third of the spec. In my case, 33 lb-ft (the spec is 100 lb-ft) and torque the lug nuts in the pattern shown above.

- Set the torque wrench to two thirds (66 ft-lb) and torque the nuts in the same pattern.

- Set the torque wrench to the full spec (100 ft-lb) and torque in the pattern once more.

Nowadays it's common for car and RV repair shops to warn you to check lug nut torque after driving for 100 km. With this method, that's not necessary; I've done spot checks and have never found a loose lug nut. When I get a vehicle back from a shop, I always loosen and re-torque the wheels this way.

__________________

2012 Rockwood Ultra-Lite 2701SS, Goodyear Endurance LRD, ProPride 3P 1400 hitch

2013 F-150 FX4 7700# GVWR SuperCrew 3.5L EcoBoost 157" WB Max Tow 3.73:1

John, Dawn and Emily... and Bella the camping kitty

visit our website at www.restcure.ca

|

|

|

09-15-2017, 05:25 AM

09-15-2017, 05:25 AM

|

#28

|

|

Senior Member

Join Date: Jul 2010

Location: Waynesville

Posts: 14,428

|

Restcure, this is the Proper way to "Torque a Wheel"!  The tire shops sometimes try to "Imitate" the "Nascar Pit Stops" which turns out badly even for some of them!  Youroo!!

__________________

|

|

|

|

|

| Thread Tools |

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Discussions

» Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|