|

|

02-14-2019, 06:33 PM

02-14-2019, 06:33 PM

|

#1

|

|

Retired Old Fart

Join Date: Nov 2018

Location: McDonough, GA

Posts: 971

|

Trailer propane lines - rubber, iron or copper?

Ok, I'm at a snag. I need to get the 5 LP hoses out of the way so I can put a new single piece underbelly back on my Freedom Express 246RKS. The problem is the original lines are all fixed IP fittings into a distribution block in the approximate middle of the camper on the underside. I need to take the lines off to wrangle the big piece of coroplast into place, but those fittings are fixed. So it appears I will need to disconnect the flare end at the individual appliances and then drop the entire line assembly out. Pretty much everything from the LP regulator the each appliance is basically one octopus assembly with fixed fittings. Even if I wanted to slit the belly material to let the lines in to where they transition up to the appliances, I don't think I can get that one piece of coroplast under the trailer as all the other lines are in the way.

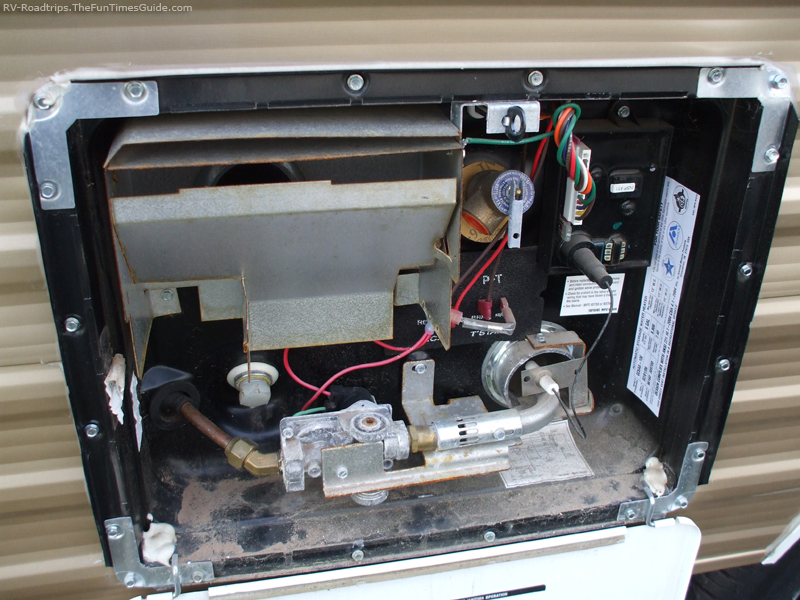

Here is the distribution block and those dang fixed connections. As was previously pointed out I will have to unhook the other end of each hose so I can turn the entire hose to unscrew these from the distribution manifold (basically a block with threaded holes in it).

So here is my question. If I have to take this monster of a hose assembly out anyway, why not make what goes back in more user friendly for future repairs, mods, etc... I know eventually I will need to fix something and either the underbelly or a LP line will be in the way.

My last TT was a 1998 model and had black iron pipe under the frame for the LP lines with soft copper to the individual appliances. All the newer ones seem to have these rubber LP lines. Is there any advantage to rubber vs iron pipe or Type L copper (other than to the factory - easier to store and install for them)?

Iron pipe has been around forever and we know it works. Also I've seen TT plumbed entirely with soft copper lines. I'm talking about the stiffer type L 1/2" copper main lines with soft copper 3/8" distribution runs to the appliances. I can solder the fittings and make the flare connections for the appliances. If I break down in East Jesus, Montana, there is probably a hardware store with copper, fittings, a propane torch and solder if I need to repair the LP lines (doubt it will ever happen short of an object bouncing up and damaging a line). If a line is nicked by a road object, I can solder in a splice, etc... You get the idea.

So is there any reason not to use a shorter flexible rubber hose from the LP tanks to the front of the TT and then run hard Type L copper the rest of the way with Copper T & L fittings stepping down to the 3/8" soft copper final run to the appliance.

Or is there some issue I'm not thinking of here?

__________________

Just the 2 of us in a...

"Currently between trailers"

Sold the 246RKS in 2023

|

|

|

02-14-2019, 06:42 PM

02-14-2019, 06:42 PM

|

#2

|

|

Senior Member

Join Date: Jun 2015

Location: Pensacola, FL

Posts: 1,645

|

Due to movement in the chassis as you travel, I would nix the black pipe. The copper should be fine as long as you run it with some curves and slip-style support clamps that allow some movement.

__________________

2019 Coachmen Freedom Express 192RBS

2015 T12RBST Flagstaff Hardside

Disclaimer: The actual value of my "Two Cents" of advice varies just like a bitcoin.

|

|

|

02-14-2019, 07:25 PM

02-14-2019, 07:25 PM

|

#3

|

|

Retired Old Fart

Join Date: Nov 2018

Location: McDonough, GA

Posts: 971

|

Quote:

Originally Posted by Bluepill

Due to movement in the chassis as you travel, I would nix the black pipe. The copper should be fine as long as you run it with some curves and slip-style support clamps that allow some movement.

|

Yes I would use the rubber lined cable clamps to keep the hard and soft copper lines in place, but allow for some movement (sort of like a floating assembly under the trailer). The rubber will also keep the copper from contacting the steel frame and help prevent any electrolysis between dissimilar metals. I'm thinking there is not going to be any metal to copper contact at all under the trailer. Clamps like these.

__________________

Just the 2 of us in a...

"Currently between trailers"

Sold the 246RKS in 2023

|

|

|

02-14-2019, 07:38 PM

02-14-2019, 07:38 PM

|

#4

|

|

Senior Member

Join Date: Apr 2017

Location: PA - Pennsylvania

Posts: 151

|

Corrugated stainless steel tubing (csst) is an option to soft copper or rubber tubing and readily available.

http://homeflex.com

__________________

2015 Tracer 3140RSD Touring

2016 Nissan Titan XD Diesel

Blue Ox Swaypro BXW1500

|

|

|

02-15-2019, 02:21 PM

02-15-2019, 02:21 PM

|

#5

|

|

Senior Member

Join Date: Jan 2015

Location: West Michigan

Posts: 641

|

Never use copper tubing. Propane and copper do not get along with each other. The copper will be damaged by the propane and flake off insde the pipe and plug the tiny orifaces in the system.

|

|

|

02-15-2019, 02:40 PM

02-15-2019, 02:40 PM

|

#6

|

|

Senior Member

Join Date: Feb 2016

Location: NJ

Posts: 606

|

Quote:

Originally Posted by TimVWulp

Never use copper tubing. Propane and copper do not get along with each other. The copper will be damaged by the propane and flake off insde the pipe and plug the tiny orifaces in the system.

|

Kindly provide a source for this information. My home propane lines are all copper as are those in most homes I've seen using propane. Years ago black IP was used for natural gas and possibly propane (I was a plumber's helper and installed many natural gas water heaters using black IP) but today copper is apparently approved propane piping in most states for homes. I've lived in my house for 45 years and never had a clogged copper propane line.

My two 5th wheels had and have copper propane piping.

Thus a source for your questionable information would be greatly appreciated.

__________________

DrLewie

Flemington, NJ

Former: 2007 Cardinal 30W LE

Now:2018 Arctic Fox 27-5L

2008 Ford F-250 Long Bed Diesel

Total of 30 Months on the Road Since 2008

|

|

|

02-15-2019, 03:19 PM

02-15-2019, 03:19 PM

|

#7

|

|

Pickin', Campin', Mason

Join Date: Aug 2015

Location: South Western PA

Posts: 19,143

|

Quote:

Originally Posted by TimVWulp

Never use copper tubing. Propane and copper do not get along with each other. The copper will be damaged by the propane and flake off insde the pipe and plug the tiny orifaces in the system.

|

I have never heard this and apparently neither have any of the major R/V manufacturers as ALL of my R/Vs through the years have had copper tubing somewhere as supply lines for the LP system. (ie: water heater, stove/oven, refrigerator)

Several local Propane Gas companies in our area connect 100 Lb. Extend-A-Stay tanks to the R/Vs in a neighboring campground and they all use copper.

All the homes in our area that use LP for cooking are connected with copper as well.

__________________

2022 Cedar Creek 345IK 5th Wheel•Solar & Inverter•2024 Ford F-Series SCREW•7.3L•4x4•Factory Puck•B&W Companion•TST Tire Monitor w/Repeater•Sinemate 3500w Gen.

F&AM Lodge 358 Somerset, PA - JAFFA Shrine - Altoona, PA

Days Camped ☼ '19=118 ☼ '20=116 ☼ '21=123 ☼ '22=134 ☼ '23=118☼ '24=90

|

|

|

02-15-2019, 04:47 PM

02-15-2019, 04:47 PM

|

#8

|

|

Senior Member

Join Date: Jan 2018

Location: Raleigh, NC

Posts: 9,584

|

Right!

Quote:

Originally Posted by DrLewie

Kindly provide a source for this information. My home propane lines are all copper as are those in most homes I've seen using propane. Years ago black IP was used for natural gas and possibly propane (I was a plumber's helper and installed many natural gas water heaters using black IP) but today copper is apparently approved propane piping in most states for homes. I've lived in my house for 45 years and never had a clogged copper propane line.

My two 5th wheels had and have copper propane piping.

Thus a source for your questionable information would be greatly appreciated.

|

Agree with Dr Lewie. The poster was probably confusing copper with zinc. Black iron pipe is used with propane and natural gas because the zinc in galvanized iron pipe flakes off and clogs regulators and orifices.

Larry

|

|

|

02-15-2019, 04:51 PM

02-15-2019, 04:51 PM

|

#9

|

|

Senior Member

Join Date: Jul 2017

Posts: 4,056

|

Quote:

Originally Posted by TimVWulp

Never use copper tubing. Propane and copper do not get along with each other. The copper will be damaged by the propane and flake off insde the pipe and plug the tiny orifaces in the system.

|

You are correct but copper has been and is still in use for propane delivery in RV ,s the number of yrs it takes for the copper to deteriorate the RV will be dust by then

|

|

|

02-15-2019, 04:54 PM

02-15-2019, 04:54 PM

|

#10

|

|

Senior Member

Join Date: Jan 2018

Location: Raleigh, NC

Posts: 9,584

|

How about this approach?

Quote:

Originally Posted by dward51

Ok, I'm at a snag. I need to get the 5 LP hoses out of the way so I can put a new single piece underbelly back on my Freedom Express 246RKS. The problem is the original lines are all fixed IP fittings into a distribution block in the approximate middle of the camper on the underside. I need to take the lines off to wrangle the big piece of coroplast into place, but those fittings are fixed. So it appears I will need to disconnect the flare end at the individual appliances and then drop the entire line assembly out.

...

Here is the distribution block and those dang fixed connections. As was previously pointed out I will have to unhook the other end of each hose so I can turn the entire hose to unscrew these from the distribution manifold (basically a block with threaded holes in it).

...

Or is there some issue I'm not thinking of here?

|

You may have overlooked one of my suggestions in our discussion yesterday. Let me restate it. Perhaps that will make it more obvious.

You don't have to remove the hoses. Just loosen or remove the flare fittings at the remote ends. Then loosen or remove any clamps you can see. Then you should be able to remove the fixed end fitting from the block by spinning the entire hose while it is in place. Even if it goes through a 90-degree turn someplace in the wall, it will probably spin.

Don't write this approach off until you've tried it.

Larry

|

|

|

02-15-2019, 04:55 PM

02-15-2019, 04:55 PM

|

#11

|

|

Senior Member

Join Date: Jul 2017

Posts: 4,056

|

Quote:

Originally Posted by dward51

Ok, I'm at a snag. I need to get the 5 LP hoses out of the way so I can put a new single piece underbelly back on my Freedom Express 246RKS. The problem is the original lines are all fixed IP fittings into a distribution block in the approximate middle of the camper on the underside. I need to take the lines off to wrangle the big piece of coroplast into place, but those fittings are fixed. So it appears I will need to disconnect the flare end at the individual appliances and then drop the entire line assembly out. Pretty much everything from the LP regulator the each appliance is basically one octopus assembly with fixed fittings. Even if I wanted to slit the belly material to let the lines in to where they transition up to the appliances, I don't think I can get that one piece of coroplast under the trailer as all the other lines are in the way.

Here is the distribution block and those dang fixed connections. As was previously pointed out I will have to unhook the other end of each hose so I can turn the entire hose to unscrew these from the distribution manifold (basically a block with threaded holes in it).

So here is my question. If I have to take this monster of a hose assembly out anyway, why not make what goes back in more user friendly for future repairs, mods, etc... I know eventually I will need to fix something and either the underbelly or a LP line will be in the way.

My last TT was a 1998 model and had black iron pipe under the frame for the LP lines with soft copper to the individual appliances. All the newer ones seem to have these rubber LP lines. Is there any advantage to rubber vs iron pipe or Type L copper (other than to the factory - easier to store and install for them)?

Iron pipe has been around forever and we know it works. Also I've seen TT plumbed entirely with soft copper lines. I'm talking about the stiffer type L 1/2" copper main lines with soft copper 3/8" distribution runs to the appliances. I can solder the fittings and make the flare connections for the appliances. If I break down in East Jesus, Montana, there is probably a hardware store with copper, fittings, a propane torch and solder if I need to repair the LP lines (doubt it will ever happen short of an object bouncing up and damaging a line). If a line is nicked by a road object, I can solder in a splice, etc... You get the idea.

So is there any reason not to use a shorter flexible rubber hose from the LP tanks to the front of the TT and then run hard Type L copper the rest of the way with Copper T & L fittings stepping down to the 3/8" soft copper final run to the appliance.

Or is there some issue I'm not thinking of here? |

Maybe i'm not understanding your problem . all those fittings are threaded into the block . just go to copper 3/8 . i'm sure they used the flexible lines for ease of installation

|

|

|

02-15-2019, 05:04 PM

02-15-2019, 05:04 PM

|

#12

|

|

Member

Join Date: Oct 2017

Location: Newburgh, IN

Posts: 61

|

Quote:

Originally Posted by TimVWulp

Never use copper tubing. Propane and copper do not get along with each other. The copper will be damaged by the propane and flake off insde the pipe and plug the tiny orifaces in the system.

|

You may be thinking of natural gas. Natural gas and copper tubing do not get along and will do exactly what you say. I've seen copper tubing completely plugged when used on natural gas.

|

|

|

02-15-2019, 07:33 PM

02-15-2019, 07:33 PM

|

#13

|

|

Retired Old Fart

Join Date: Nov 2018

Location: McDonough, GA

Posts: 971

|

Quote:

Originally Posted by Larry-NC

You may have overlooked one of my suggestions in our discussion yesterday. Let me restate it. Perhaps that will make it more obvious.

You don't have to remove the hoses. Just loosen or remove the flare fittings at the remote ends. Then loosen or remove any clamps you can see. Then you should be able to remove the fixed end fitting from the block by spinning the entire hose while it is in place. Even if it goes through a 90-degree turn someplace in the wall, it will probably spin.

Don't write this approach off until you've tried it.

Larry

|

No, I had not missed that Larry. I was originally trying not to have to disconnect the lines at the 4 appliance ends. But the more I ponder my solutions, I'm starting to think I will have to do this. So now I'm starting to think if I have to do all that work to take all the hoses completely out, I should make it easier to deal with in the future.

I'm thinking once the hoses are out, take them to a hydraulic hose shop (several in the area) and have them cut off the FIP connectors and swage on swivel flare connectors. Then thread in a FIP to flare adapter into the distribution block for each port. That way if I have something nick one of the rubber lines I can unthread and work on that 1 line instead of taking the entire assembly out again.

Is there any reason not to use flare connections under the trailer belly?

Or was a straight FIP connector used for a reason or was just a choice FR made? Plan "B" is starting to look like copper main and branch lines with soldered connections and a rubber feeder in the front of the trailer from the tanks.

__________________

Just the 2 of us in a...

"Currently between trailers"

Sold the 246RKS in 2023

|

|

|

02-15-2019, 07:34 PM

02-15-2019, 07:34 PM

|

#14

|

|

Senior Member

Join Date: Apr 2017

Location: 8300 Feet - Rocky Mountains

Posts: 2,473

|

Soft copper with flare fittings is typical plumbing for propane. All the parts are readily available at your local hardware store, and there's no nonsense with swaged or crimped types of hose end fittings that must usually be fabricated. Flaring tools are cheap.

Your manifold would probably work with the pipe-thread end of flare fittings, too.

If you can get some or all of the fittings out of the manifold, you could keep your hoses and definitely put them back with a flare union, two of these: 3/8" male npt to 3/8" male flare AND a 3/8" npt brass coupler for the hose ends to connect to one of the male flares. Ignore that some of that stuff is 1/2"....I was just looking for illustrations. Home Depot should have all of this stuff, but as you can see, Amazon has it. It's common stuff. This would be a permanent adaptation that would let you drop the manifold any time you needed to get into the underbelly.

I'd be reluctant to use hard copper or black iron pipe simply due to the vibration this plumbing must endure. Rigid materials rattling around are vulnerable to cracking. And the underside of an RV isn't exactly an ideal place to hang black pipe.

But...just curious. I've worked with a lot of hydraulic hoses. This is a long shot. Looking at your manifold, have you tried unscrewing any of the fittings? (I imagine you have...) It would be hard to assemble that mess at the factory if those nuts didn't spin free on the ends of the hoses. Of course, they could have pre-assemble the whole mess and then have the more easily disassembled fittings at the appliance end, but I think it would be worth trying to back one of those out and see if the nut spins free on the end of the hose. GENTLY hold the swaged/crimped part of the hose fitting and see if the nut will turn independently.

If you don't get lucky, it strikes me that you might disconnect the delivery end at 2 or 3 appliances, then drop that whole mess down enough to slide in the underbelly, then put it all back as it was. If any of the hoses are "too short" when you go to put them back, y ou might be able to extend them just a bit. The example is 5', but I've seen them as short at 12" at the local hardware store.

That's a whole lot of conjecture on my part, but I know you were just looking for ideas.

__________________

Jim & Renee

2020 Jayco Jay Feather X-213

previously 2014 Forest River/Rockwood HW 277

2006 Ram 1500 4WD Crew with Firestone Airbags

Every weekend boondocking in the National Forests or at Lake Vallecito.

|

|

|

02-15-2019, 08:01 PM

02-15-2019, 08:01 PM

|

#15

|

|

Senior Member

Join Date: Jan 2018

Location: Raleigh, NC

Posts: 9,584

|

My guess

Quote:

Originally Posted by dward51

No, I had not missed that Larry. I was originally trying not to have to disconnect the lines at the 4 appliance ends. But the more I ponder my solutions, I'm starting to think I will have to do this. So now I'm starting to think if I have to do all that work to take all the hoses completely out, I should make it easier to deal with in the future.

I'm thinking once the hoses are out, take them to a hydraulic hose shop (several in the area) and have them cut off the FIP connectors and swage on swivel flare connectors. Then thread in a FIP to flare adapter into the distribution block for each port. That way if I have something nick one of the rubber lines I can unthread and work on that 1 line instead of taking the entire assembly out again.

Is there any reason not to use flare connections under the trailer belly?

Or was a straight FIP connector used for a reason or was just a choice FR made? Plan "B" is starting to look like copper main and branch lines with soldered connections and a rubber feeder in the front of the trailer from the tanks.

|

My guess is that FR used stock pre-made hoses which only need a rotating connector on one end.

The only good reason I can think of to not put flare fittings and adapters on the other ends is that it will extend the rigid length of each hose about an inch. If any of the hoses takes a sharp turn right at the distribution point, it might not fit. Looking at your photo, I can't tell about the one at the upper right.

Larry

|

|

|

02-15-2019, 08:05 PM

02-15-2019, 08:05 PM

|

#16

|

|

Senior Member

Join Date: Jan 2018

Location: Raleigh, NC

Posts: 9,584

|

By the way...

Quote:

Originally Posted by dward51

No, I had not missed that Larry. I was originally trying not to have to disconnect the lines at the 4 appliance ends. But the more I ponder my solutions, I'm starting to think I will have to do this. So now I'm starting to think if I have to do all that work to take all the hoses completely out, I should make it easier to deal with in the future.

I'm thinking once the hoses are out, take them to a hydraulic hose shop (several in the area) and have them cut off the FIP connectors and swage on swivel flare connectors. Then thread in a FIP to flare adapter into the distribution block for each port. That way if I have something nick one of the rubber lines I can unthread and work on that 1 line instead of taking the entire assembly out again.

Is there any reason not to use flare connections under the trailer belly?

Or was a straight FIP connector used for a reason or was just a choice FR made? Plan "B" is starting to look like copper main and branch lines with soldered connections and a rubber feeder in the front of the trailer from the tanks.

|

By the way, if you do pull out the hoses, attach a piece of nylon twine or similar to the flare end of each before you pull it out. You can use that to pull the hose back into place. If you are going to take the hoses to a shop, tag each piece of twine and each hose with a unique number, so you won't have to figure out what goes where.

Larry

|

|

|

02-15-2019, 08:49 PM

02-15-2019, 08:49 PM

|

#17

|

|

Retired Old Fart

Join Date: Nov 2018

Location: McDonough, GA

Posts: 971

|

Quote:

Originally Posted by Larry-NC

By the way, if you do pull out the hoses, attach a piece of nylon twine or similar to the flare end of each before you pull it out. You can use that to pull the hose back into place. If you are going to take the hoses to a shop, tag each piece of twine and each hose with a unique number, so you won't have to figure out what goes where.

Larry

|

Yep, I had already planned on that one. The fridge and oven are the 2 runs that are not straight up through the floor and have a 2nd level to go through. So a pull line is a for sure with those.

I wish there was a female pipe thread to female swivel flair adapter I could find. That way assuming those hoses are fixed pipe thread, put the above adapter on there and then a male pipe to male flair screws into the block and problem solved without having to have the hoses modified. Probably less expensive too. I just don't want to have 3 or 4 adapters in the line either. More joints, more opportunity for leaks.

Well, it's predicted to rain cats & dogs for the next 4 or 5 days (just started) with flooding so I'm not expecting to try and take it out for a bit. Good time to get my plans formulated though

__________________

Just the 2 of us in a...

"Currently between trailers"

Sold the 246RKS in 2023

|

|

|

02-15-2019, 09:00 PM

02-15-2019, 09:00 PM

|

#18

|

|

Senior Member

Join Date: Jan 2018

Location: Raleigh, NC

Posts: 9,584

|

Oh, that's too easy

Quote:

Originally Posted by dward51

I wish there was a female pipe thread to female swivel flair adapter I could find. That way assuming those hoses are fixed pipe thread, put the above adapter on there and then a male pipe to male flair screws into the block and problem solved without having to have the hoses modified. Probably less expensive too. I just don't want to have 3 or 4 adapters in the line either. More joints, more opportunity for leaks.

|

Oh, that's too easy. How about this:

A brass union and a brass close pipe nipple on the end of each hose?

I guessed the size at 1/4" IP.

You can probably find them cheaper than Ferguson. That happened to be the first place I looked. And if you use them, you might have to stand the box off its mounting plate a bit for to clear the unions.

Larry

|

|

|

02-15-2019, 09:14 PM

02-15-2019, 09:14 PM

|

#19

|

|

Retired Old Fart

Join Date: Nov 2018

Location: McDonough, GA

Posts: 971

|

That would work, but it may be less expensive to swage on a new female swivel and be done with it.

__________________

Just the 2 of us in a...

"Currently between trailers"

Sold the 246RKS in 2023

|

|

|

02-15-2019, 09:45 PM

02-15-2019, 09:45 PM

|

#20

|

|

Senior Member

Join Date: Jan 2018

Location: Raleigh, NC

Posts: 9,584

|

Grainger

Quote:

Originally Posted by dward51

That would work, but it may be less expensive to swage on a new female swivel and be done with it.

|

Somewhat cheaper at Grainger, and there's no shipping if you pick up at the store.

Also at PlumbingSupply.com.

Much cheaper in eBay

Larry

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Discussions

» Recent Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|